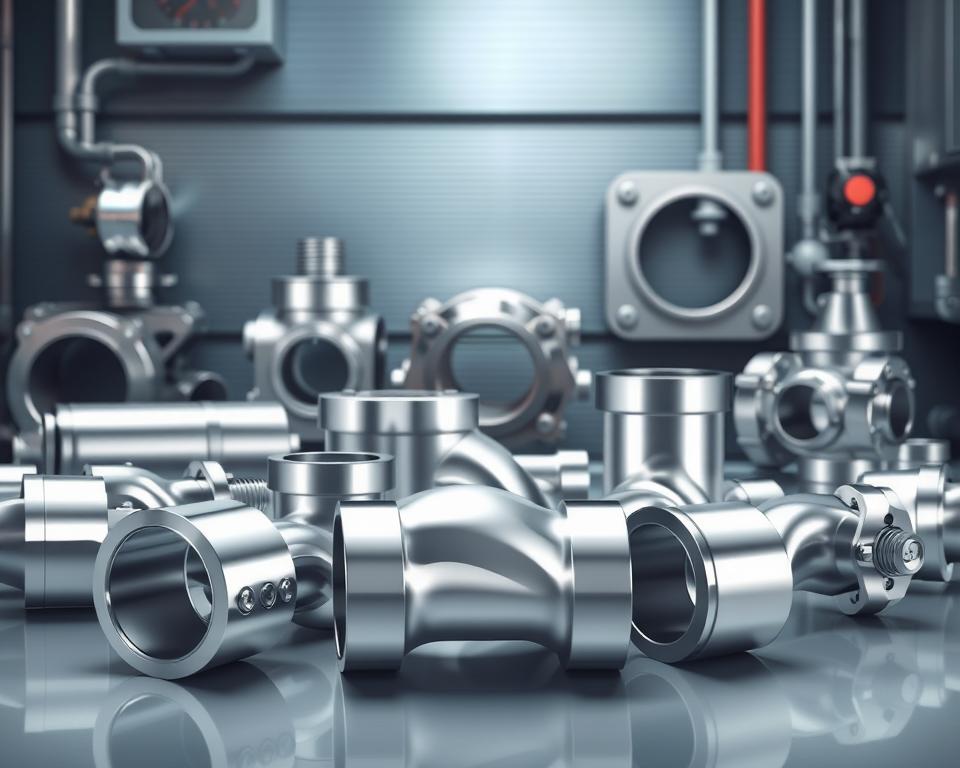

High-End Tri-Clover Sanitary Fittings for Hygiene

Within fields where sanitation is life-saving, even microscopic gaps are significant. That’s why, companies like Installation Parts Supply offer high-precision solutions aimed at reducing danger. Such hygienic connection systems merge robustness with smooth installation, rendering them a top choice for plants that insist on flawless results.

These fittings go beyond merely preventing leaks – they’re crafted for the stringent criteria of food manufacture, drink-line facilities, and pharma operations. Fabricated from anti-corrosive alloys, they handle regular sterilizations while keeping rigidity. The build mindset aligns with industry leaders like Alfa Laval, placing first sanitary fittings smooth surfaces and speedy removal.

What sets these products apart? Think one-handed installation and equipment-free care. Technicians welcome the simple mechanism during hectic production schedules, while managers prioritize uniformity across pipelines. Every piece is subjected to tight verification to confirm conformity to FDA and 3-A Sanitary Standards.

Core Messages

- Adopted by industry pros for impermeable operation in critical environments

- Built using industrial-grade stainless steel for enduring toughness

- Makes it easy to meet food safety and pharmaceutical regulations

- Cuts stoppage through no-tool fitting and cleaning

- Reinforced via quality assurance protocols equalling global benchmarks

Product Overview and Key Benefits

Secure couplings are the backbone of hygienic processes. Installation Parts Supply engineers components that blend exact machining with practical functionality. Their products supply sealed reliability while streamlining service routines—critical for industries where rapid throughput meets sterility.

First-Class Quality and Clean Standards

Every piece faces intensive trials to comply with worldwide norms. The metals defy deterioration, even after frequent autoclave runs. Hermetic joints halt microbe spread, a feature hailed by dairy processors and pharmaceutical manufacturers alike.

These units emulate the standards of leaders like Alfa Laval, ensuring smooth surfaces and uniform dimensions. Flexible configurations integrate with legacy piping, lowering modification spend. Workers report 30% speedier setups compared to traditional threaded systems.

Distinct Benefits Offered

Bespoke machining sets this supplier apart. Want an odd size or special coating? Their team works hand-in-hand with customers to engineer tailored solutions. Quick shipment and 24/7 technical support keep production lines moving.

The benefits go past toughness. Quick-release separation cuts downtime during safety walkthroughs. Liquid processing sites using these connectors observe fewer production stoppages and consistent flow rates. It’s not just about hitting the rules—it’s about going beyond without strain.

Design Highlights & Technical Notes

High-accuracy design combines with modularity in current manufacturing networks. Installation Parts Supply produces components that pair precise dimensions with customizable setups. Their strategy delivers frictionless compatibility into existing setups while preserving tight cleanliness codes.

Bespoke Metals & Finishes

Every project has unique needs. That’s why materials range from 304 to 316L stainless steel, preferred for strength and corrosion resistance. Surface treatments like electro-buffing produce mirror-like smoothness, diminishing biofilm formation by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes utilize beam-based sensors to secure uniform wall thickness. Fine margins (±0.005″) prevent weak spots in high-pressure environments. During quality checks, components receive X-ray scans and pressure tests to find microscopic flaws.

Bespoke options reaches further than visuals. Clients request particular elbows, flange sizes, or purpose-built coatings for chemical resistance. These tailored options help industries comply with new rules without starting from scratch.

Tri-Clamp Fittings – Setup & Uses

Current quick-turn operations require parts that mount rapidly yet operate consistently. These joining solutions excel in environments where rapidity intersects sterility. Their design scraps complicated hardware, enabling teams to retain focus on throughput rather than assembly headaches.

Easy Installation Steps

Coupled flange rims and a centered gasket form sure-fire joints in seconds. Operators place the parts, locate the squeeze band, and hand-tighten – no wrenches required. This technique lowers setup slips while holding steady load across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Adaptable Links Between Systems

Between polished pipes and reactors, these interfaces join varied parts with ease. The uniform design couples with various diameters, enabling fast changeovers during product changeovers. Dairy plants regularly utilize them to alternate between cleaning cycles and production runs seamlessly.

Maintenance teams enjoy how components come apart for thorough sanitation. Smooth surfaces prevent residue buildup, while the lack of threads avoids bacterial hideouts. Weekly cleanings take half the time compared to older connection methods.

Application Areas & Compliance Codes

Whether in micro-breweries or biologics factories, modern facilities trust in fittings that suit different purposes while conforming to tight guidelines. Installation Parts Supply offers solutions esteemed across high-stakes domains where product purity must be absolute. Their designs unite performance with rules, engineering networks that succeed under stress.

Food, Beverage, and Pharmaceutical Sectors

Across edible product facilities, fast-shift couplings ease recipe changeovers and washdowns. Breweries rely on custom tees to manage complex flow paths minus impurity threats. Pharmaceutical manufacturers depend on sealed couplings to guard delicate ingredients during sterile transfers.

These parts arrive in many diameters to match piping layouts, from small-scale laboratories to mega fermenters. Dairy processors commend how standardized parts diminish breaks during equipment upgrades. Even subtle changes in production processes are absorbed through modular designs.

Alignment to Global Codes

Every product matches and outperforms benchmarks set by global organizations. ASME-certified materials withstand heat in pasteurization systems, while ISO-compliant finishes prevent bacterial buildup. The 3-A symbol vouches for direct contact with consumables.

Tri-Clover joints demonstrate the devotion. Their uniform dimensions ensure leak-free performance across automated lines. Third-party audits document lineage from raw materials to finished goods, supplying auditors comfort.

By aligning with these standards, facilities simplify audits and earn approvals quickly. It’s not just about avoiding fines—it’s about building consumer trust through transparent sanitation.

Last Words and Forward Path

Selecting parts that pair output and rules defines production wins. Installation Parts Supply provides systems combining durability with hygienic design, securing leak-free performance across food, pharma, and beverage environments. Their products meet rigorous standards while smoothing regular duties through simple fitment.

With alternatives of grades and sheens, solutions adapt to unique process requirements. Whether handling high-temperature fluids or constant washdowns, material choices and surface treatments extend lifespan. Professionals recognize the wide selection of connection types matched to given flow speeds and psi loads.

Placing orders is hassle-free, with specialist help on hand to pair process demands. Express delivery and agile help shrink line interruptions during upgrades or replacements. Periodic cleaning becomes effortless thanks to no-tool breakdown and glossy paths that block grime.

Prepared to boost plant dependability? Contact Installation Parts Supply to discover custom layouts – from sanitary clamp to tri-clover-style connectors – supported by top-tier QA. Their team ensures your systems meet current standards while future-proofing operations.